We looked at quite a few sites on how to make a conch horn and all the basic instructions seemed to be the same, but those instructions left a few things a little unclear to the first time horn maker. I hope I can make the instructions a little clearer.

- Choose a conch shell. One that is 7 inches or larger in length will produce the best sound quality. The larger the conch the deeper the sound, but the size of the shell has nothing to do with how loud it will play.

- If the shell isn’t clean, wash it in warm sudsy water to remove all traces of the original inhabitant, then soak the shell in a 10 to 1 water/bleach solution overnight to sanitize the shell. This will help remove the algae and crud attached to the shell. I then used a sharp knife to scrape away the tiny white crusty stuff left behind.

- The first step in making your horn is to cut off enough of the tip of the shell to leave a dime size surface (Most instructions called this a hole, but it really isn’t a hole…not yet). We used a pneumatic cut off saw (because it’s what we had and it made the job easier) in this step, but you could also use a hacksaw or dremel (pic #2). We also used this saw to round off the points of the shell to make a smoother mouthpiece (pic #3).

- The next step is to make a hole in this surface. You must drill through the spiral structure enough to allow an air passage but not so much that you remove all air restriction. We used a sanding bit on the drill press to widen the opening. This could also be done with a large drill bit (pics #4 & #5).

- Use sandpaper to smooth the edges of the mouthpiece (pic #6).

- If your shell was harvested for the conch meat it will have a hole that will need to be blocked. If small enough this can be done with our finger. We decided to use Goop to fill our holes, but epoxy and a bit of gauze can be used (pic #7).

- If you want your shell to look pretty and polished, wipe it down with a little baby oil.

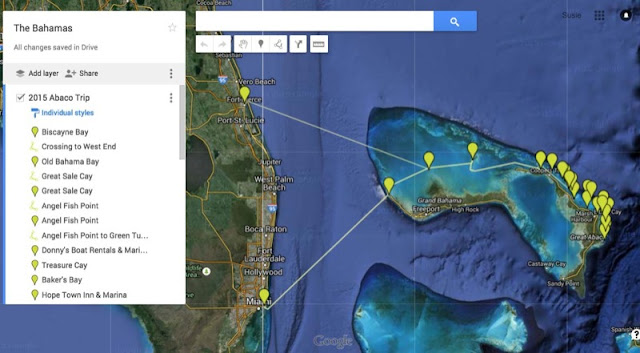

The conch shells we brought home from the Abacos

Using the saw to take off the pointed edges of the shell. (pic #3)

We used a drill in the beginning to hollow out the air passage, but it seemed a little slow. (pic #4)

So we used a sanding bit on the drill press. It was just the right size and made the job much easier. (pic #5)

Sand all edges to make a smooth mouthpiece. (pic #6)

We used a bit of fiber glass material (gauze or any material would work) on this shell to fill the hole and then applied the Goop on top of that...it worked great. (pic #7)

The finished mouthpiece. This area was completely flat when we first sawed off the tip (not a hole like in some instructions). Drilling and sanding was needed to open up the air passage.

Two of our conchs are horns and two are being used as bookends on Texas Pearl.

The next blog will be about how to blow the conch horn. They say it takes practice, but Stan must have made a great horn, because I could blow it on the first try! What a good man.